CARBON-X®-AL

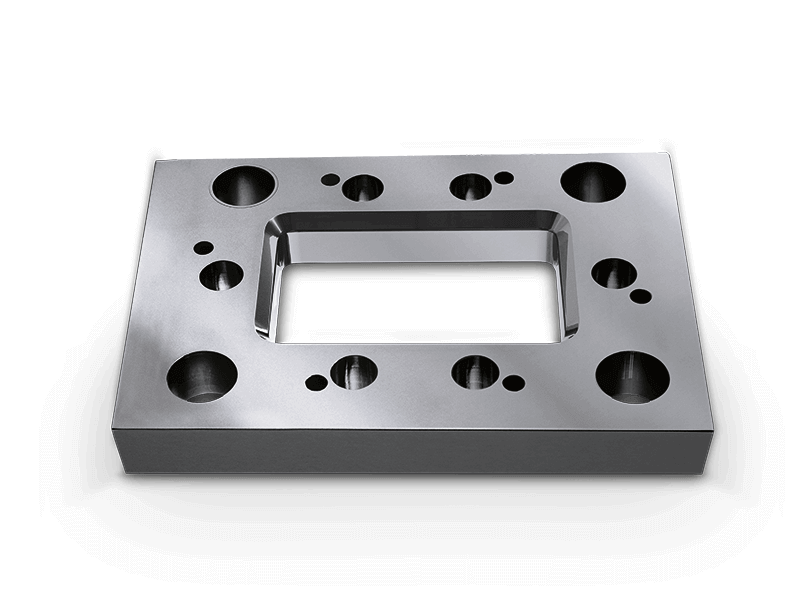

During the impact extrusion of aluminium discs, an increase in performance of approx. 76 % was achieved compared to chemically comparable coating systems. At the same time, it showed that using the eifeler sputter technology (150 – 200 °C) resulted in a low temperature load on the tool, treating the tool more careful.

| Hardness | 2.400 ± 400 HV |

| Coating thickness | 3 – 4 µm |

| Maximum operating temperature | 325 °C / 617 °F |

| Coefficient of friction against steel | 0,05 – 0,1 |

| Roughness | R0: 0,011 µm RZ: 0,109 µm |

| Colour | Dark grey |

CARBON-X®-AL

For high speeds

The DLC-based CARBON-X®-AL coating combines diamond-like hardness with the lubricity of graphite, which enables its use under reduced lubrication. This in turn leads to an environmentally friendly process that enables an overall reduction in production costs and increases your economic competitiveness.

Richard Hocke, Product Manager Forming Tools voestalpine eifeler Coating