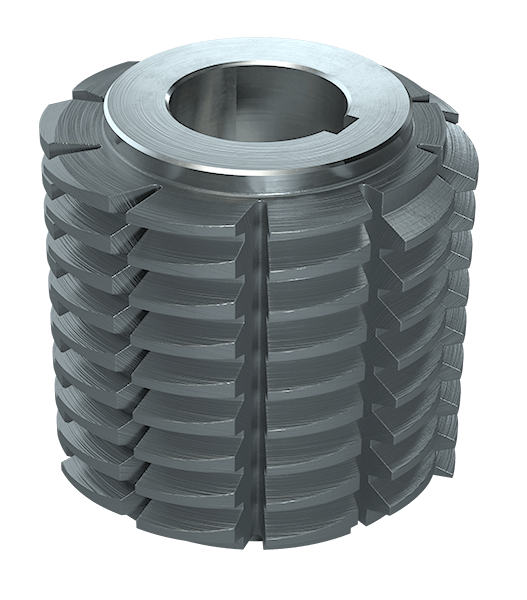

SUBLIME®

In tests with commercially available hobs, the new, innovative SUBLIME® coating was compared with other coatings. The results show increases in tool life of up to 130%.

| Hardness | 3.300 ± 200 HV |

| Coating thickness | 3,0 ± 1,0 µm |

| Maximum operating temperature | 1.100 °C / 2.012 °F |

| Friction coeff. against steel | 0,7 – 0,8 |

| Rauheit | <0,07 µm |

| Colour | Grey |

SUBLIME® is produced in the PVD systems of voestalpine eifeler Vacotec GmbH and is based on AlCrN and AlTiN as coating materials. This combination produces an impact-resistant, temperature-resistant coating with optimum adhesion. Thanks to its layer architecture and elements, SUBLIME® achieves top wear resistance, even at the high temperatures that often occur in gear teeth.

SUBLIME®

For high speeds

Planetary gears from Neugart

Technical application support

Düsseldorf

T: +49 211 97076-0

F: +49 211 97076-955

Technical application support

Ettlingen

T: +49 7243 5778-0

F: +49 7243 5778-20

Technical application support

Schnaittach

T: +49 9153 9227-0

F: +49 9153 9227-65

Technical application support

Salzgitter

T: +49 5341 2232-0

F: +49 5341 2232-14