Heat Treatment

Vacuum Heat Treatment Services

Heat treatment is the process of heating metal and then cooling it in a controlled way so as to select desired mechanical properties. Heat treatment prepares a substrate for a better PVD adherence by tempering and hardening the tool or component. We work with our clients to make sure we choose a heat treatment process that is ideal for their components and processes.

At voestalpine Thermo-Tech, we offer a wide range of vacuum heat treatment services for tempering & hardening of tool steels. Our thermal processing center has an extensive line of vacuum heat treatment equipment to suit all of our customers’ requirements, accommodating tools and components of a wide range of size and/or complexity. We have built our success and reputation on value engineering, practical innovations, attention to detail, unparalleled product quality, and on long-term client relationships.

Our goal is to provide our customers with a complete experience, from the very first stages of material selection, to the final stages of post-heat treatment recommendations. Our engineers and metallurgists are available to our clients at all times to ensure that the heat treatment process is ideal for your company’s products.

Our organization remains at the industry’s forefront by maintaining memberships in major manufacturing and service associations such as: American Society for Materials (ASM), Canadian Plastics Industry Association (CPIA), North American Die Casting Association (NADCA), Ontario Aerospace Council, the Society of Manufacturing Engineers (SME), as well as other associations.

At voestalpine Thermo-Tech, we also understand that turnaround time can’t be overlooked. Our heat treatment facility operates 24 hours a day, 7 days a week. We strive to function as a natural extension of our customers’ supply chain. We focus on quality, while at the same time ensuring our clients’ heat treatment needs are fulfilled in a timely manner. We aim to exceed your expectations and provide you with outstanding customer service and quality assurance.

Our capabilities include:

- Nitriding

- ThermoniteSM (Gaseous Ferritic Nitro-Carburizing)

- CryothermSM (Cryogenic Treatment)

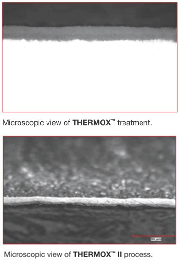

- ThermoxSM , Thermox II (Steam Oxidation Treatment)

- Tempering (Vacuum, Atmosphere)

- Stress Relieving (Vacuum, Atmosphere)

- Annealing (Vacuum, Atmosphere, Bright)

- Precipitation Hardening (Ageing, Solution Annealing)

- Normalizing

- Homogenizing

- Welding

- Customized Racks / Fixturing

Explore our Heat Treatment Capabilities