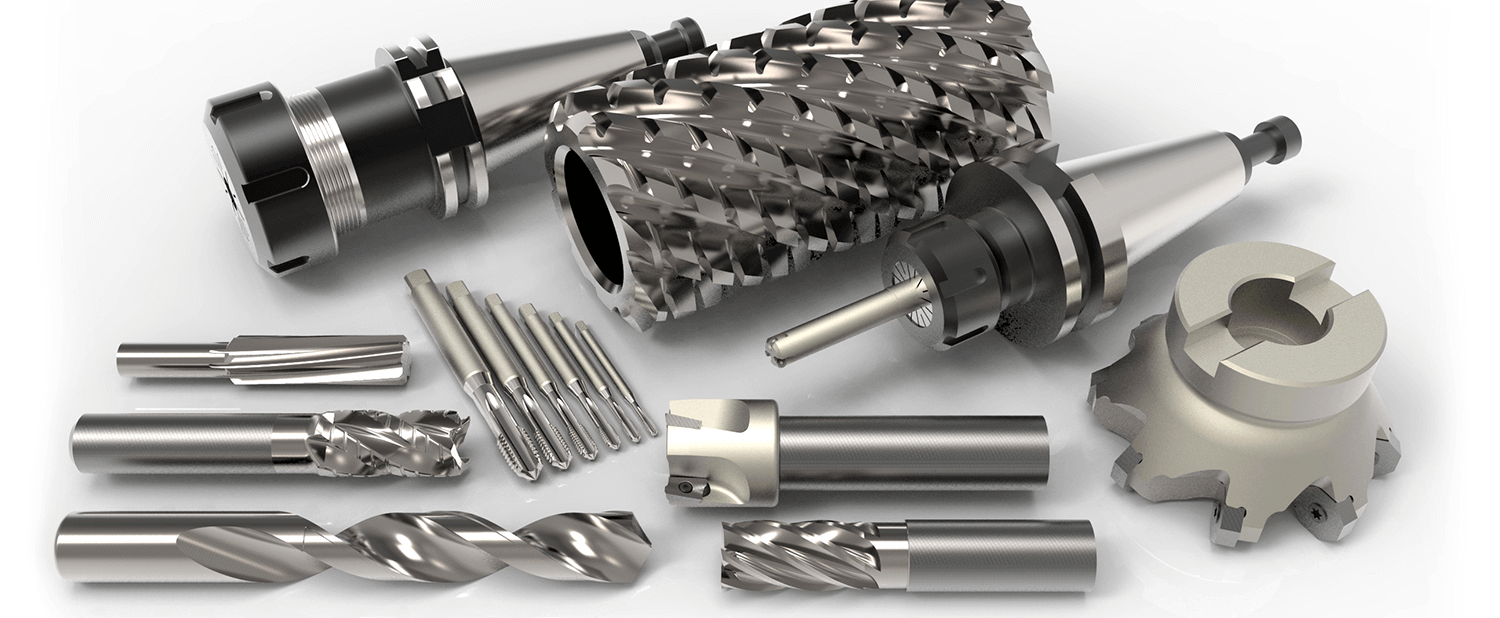

Cutting Tools

Relied upon to transform raw materials into precision components, cutting tools play an integral role in the manufacture of everything from small electronic devices to massive machinery. Excessive heat, wear, and other detrimental factors between contacting surfaces, however, can bring production to a halt.

If you are looking to boost cutting tool performance, voestalpine eifeler Group is here to help. Our series of Physical Vapor Deposition coatings, or PVD coatings, have been shown to provide the best solutions with even the most challenging machining operations, helping you gain a competitive advantage in your industry.

Why Does Cutting Tool Wear Matter?

Machine tools are devices used to perform a range of manufacturing processes, such as drilling, milling, turning, honing, routing, and cutting of a workpiece. As the modern manufacturing industries demand higher and higher output efficiency through higher material removal rate (i.e., increased speed and feed), premature failure could happen on cutting tools, such as:

-Excessive flank wear

-Edge build-up

-Thermal cracking

-Excessive crater wear

-Breakage/chipping of cutting edges

These premature failure from cutting tools could lead to the defect on finished parts such as:

-Galling / Adhesive wear

-Scoring / Abrasion wear

-Chipping

-Thermal cracking

– Flank wear

– Crater wear

– Edge wear and rounding

-Deformation and fractures

– Material microstructure unwanted changes.

These defects will produce overall increased tooling cost, labor cost, machine maintenance/repair cost and decreased output efficiency. Ultimately it will lead to expensive recalls, generate negative customer feedback, harm the company reputation, and lose market share.

Take Cutting Tool Performance to New Heights

The primary cause of cutting tool degradation is heat generated from high- or ultra-high-speed usage. PVD coatings from the voestalpine eifeler Group have been shown to improve cutting tool thermal stability, even for the most demanding applications.

Unlike standard coatings such as AlTiN, TiCN and TiN, our own new generation of high-performance coatings like SUBLIME®, CROSAL®-PLUS, SISTRAL® AND DLC provide a variety of advantages:

-Improved tool life and overall reduced part cost/piece.

-Better finish and tighter tolerance on work pieces.

-Enable higher cutting speed and feed rates.

-More environmentally friendly machining operation with potentially reduced coolant consumption or even dry machining.

Bespoke Cutting Tool Coating Solutions

When it comes to manufacturing, there is no such thing as a one-size-fits-all operation. Therefore, we recommend selecting the best coating for your operation to take the maximum advantage of what our high-performance coatings can offer.

Years of research and development in PVD coatings for cutting tools, including carbide tooling, allow voestalpine eifeler Group to provide you with solutions that have proven to be extraordinarily successful. Our newest series of PVD coatings includes:

Our newest PVD technology with exceptional impact resistance at elevated temperatures for the harshest operations. Perfect for gear cutting.

Outstanding hot hardness combines with superior coating adhesion. Suitable for a wide variety of workpiece materials. Ideal substitute when AlTiN does not perform.

A coating suitable for high-speed dry machining of hardened materials.

Super smooth PVD coatings ideal for micro tools, taps and reamers demanding tight tolerance and sharp cutting edges. Series including Ultra-fine TiN, Ultra-fine TiCN and Ultra-fine SISTRAL

Our high hardness, low friction DLC coating offering for Aluminum, copper/brass and reinforced plastic machining solution

Stable at elevated temperatures applications where abrasion resistance is required. Suitable for hard machining.

Work With Us

Our PVD coatings are developed to be effective, long-lasting, and easy to use. If you’re unsure which coating is best for your application, please reach out to us. Just tell us about your process and what you want to accomplish. We have the best technical team on the market – another benefit for you.

Contact us to learn more about PVD cutting tool coatings.