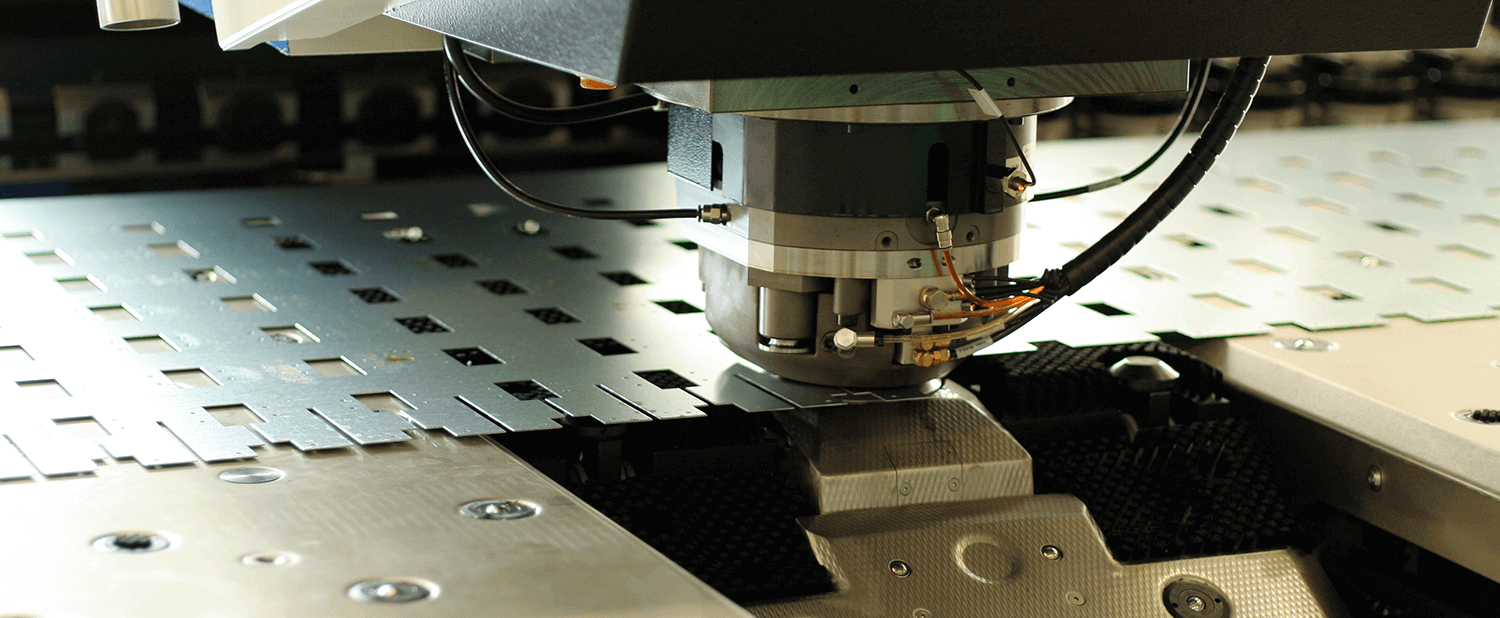

Stamping & Forming

Capable of quickly converting flat metal sheets into specific shapes, stamping and forming processes are used to manufacture all sorts of components. Without adequate tooling protection, however, excessive wear can bring production to a halt.

Get the most from your metal stamping and forming line tooling with support from voestalpine eifeler Group. Our series of Physical Vapor Deposition coatings (PVD coatings) have been shown to protect against premature wear, cracking, and thermal failure.

The Impact of Tool Wear

Stamped or formed parts are produced by placing sheets into presses, where it’s molded into a net shape by tooling driven at extreme forces. However, many issues can arise when tooling and workpiece surfaces come into direct contact without proper protection.

-Galling / Adhesive wear

-Scoring / Abrasion

-Deformation

-Cracking

-Unwanted Heating, changing material characteristics

Exact issues vary by the process, but without mitigation they can lead to batches of nonconforming finished products.

Hot Stamping

Hot stamping has rapidly become a complement to cold forming in the automotive industry. Parts can be made larger, stronger, and more complex by using a heated blank that forms and hardens quickly in the die. A risk associated with this process is premature tool failure.

Bending

In bending, there’s ordinarily only deformation about one axis. Tool steel selection depends primarily on the material’s type, strength, and thickness as well as part complexity. The most critical failure mechanisms for bending are abrasive and adhesive wear for softer materials or abrasion, adhesive wear, galling, and deformation for harder ones.

Press Forming

This is a cold-bending operation used to shape, flange, or make shallow impressions in a part previously blanked out or sheared from a sheet. For softer materials, common failure mechanisms for press forming are abrasive and adhesive wear. Abrasion, adhesive wear, galling, and deformation are areas of concern for harder materials.

Deep Drawing

In this forming operation, the material is drawn into a die cavity and the flow is controlled by a blank holder. The most critical failure mechanisms for bending are abrasive and adhesive wear and galling for softer materials, whereas abrasion, adhesive wear, galling, and deformation are typical for harder ones.

The Coating for Metal Stamping Experts

PVD coatings from the voestalpine eifeler Group have been shown to greatly improve stamping and forming tool durability and performance, even for the most demanding applications. Unlike standard coatings, they feature a thin ceramic layer renowned for very high hardness and low friction. This provides a variety of advantages and benefits:

-Improves tooling lifespan

-Creates a thermal barrier between the tool and workpiece providing a high temperature stability

-Increases tooling lubricity reducing lubricant consumption

-Strengthens tooling wear resistance

-Toughness

-Low coefficient of friction

-Higher productivity

-Less down time

-Lower tooling cost

Custom Forming Steel Coatings Mean Better Tooling Functionality

No two stamping or forming applications are identical, so there’s no such thing as a one-size-fits-all coating solution. At the voestalpine eifeler Group, we’ve developed an entire series of coatings to meet specific needs.

–VARIANTIC® / DUPLEX-VARIANTIC® / DUPLEX-VARIANTIC®-1000

–TiCN (Titanium Carbo-Nitride)

Here For You

Whether you’re looking for stamping or forming steel coatings, voestalpine eifeler Group has a solution. We’re happy to help you find the optimal PVD coating for your process. We have the best technical advisors in the market, our experience and availability allow you to have years of knowledge at your service.

Just tell us about your operation and goals as well as the issues you’re facing.

Contact us to learn more about our coatings for metal forming tools applications.

Find your nearest eifeler site

Downloads

- Coating Selection Guide pdf | 301 KB

- PVD Coating for Stamping and Forming Applications Brochure pdf | 807 KB

- Duplex – VARIANTIC® Brochure pdf | 624 KB